graphicdesign.about.com

Audience

When beginning a project, it is important to think about the experience of your audience, which differs greatly between print and web design. At the most basic level, the web is interactive and print pieces are usually not.

In print, you are trying to get your audience to stay on a page long enough to get a marketing message across. You are often faced with a limited area in which to achieve this, such as a one-page magazine ad. In some cases, you are trying to catch their attention and have them dive deeper into your product, as with a book cover or the first page of a brochure. One of the benefits of print design is that you are dealing with a physical product, so physical properties such as texture and shape can help you achieve your design goals. As an example, paper companies will take out magazine ads printed on their own paper, allowing the audience to feel the weight and texture of their product.

Layout

- In print, your space is generally measured in inches.

- You can be dealing with anything from a business card to a highway billboard.

- You know the space allowed from the start and that your finished product will look the same to everyone who sees it.

- You must have bleed and safety areas to guarantee print results.

Colour

- Consider the difference between your colors on screen and on paper.

- Again, a “proof” can help ensure you are getting the desired results.

- You often choose “spot” or “process” colors for your printer to use. These are colors you choose from a palette and identify with a code that you provide to your printer.

It is important to prepare and design your documents correctly to ensure that the final PDF will output correctly and to the best quality. This page highlights some of the main issues to be aware of when designing for print.

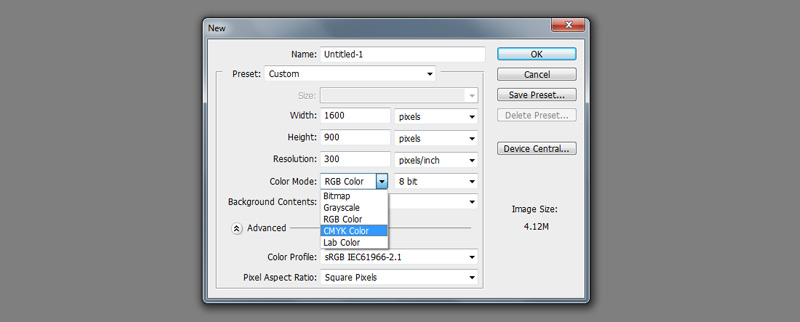

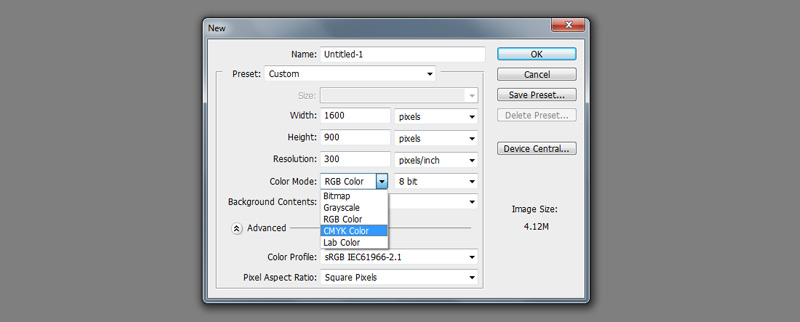

Colour space

Files intended to print in four-colour process should be supplied in the DeviceCMYK colour space, and contain only cyan, magenta, yellow, and black. Any objects in RGB, calibrated RGB or LAB must be converted before being imported into your layout application.

Total Area Coverage (TAC)

Combined colour values should not exceed 300 per cent. This may be required to be lower depending on the paper being printed on. This TAC applies to pictures printed in colour - 300 per cent in the darkest areas.

Image specification

Resolution and size

Colour and greyscale continuous-tone images should be saved at 300dpi at a print size relevant to its final size on the page. Bitmap images (linework) should be saved at at least 1200dpi and preferably 2400dpi. Resolutions lower than this or images smaller than the final size on the page will lead to a loss of quality.

Format and Compression

Ideally, images should be saved as TIFFs, but JPEG compression can be used to reduce file size. I do not recommend the use of RAW files from digital cameras or PhotoShop .psd files as results can be unpredictable if not properly handled.

JPEG compression is a "lossy" format where pixel information is thrown away to reduce file size. Algorithms rebuild the discarded data when the file is decompressed. LZW compression within the TIFF format is a lossless method, replacing repeating code with a tag which is replaced when the file is decompressed.

Vector graphics

Files originated in vector-based illustration software such as Adobe Illustrator should have all fonts embedded or outlined. The colour space should be CMYK and all transparency must be flattened.

Placing graphics

When you place pictures in your layout application allow a "safety margin" between the edge of the picture box and any part of the image that is not meant to appear. This will avoid "rebates", particularly noticeable when you place keylines around your images.

Fonts

Do not style fonts bold and/or italic using the styling buttons in your layout application. Always select the styled version of the font from the font list. If this is not possible, remember that not all fonts have bold and italic versions.Your screen does not recognise this and will display them regardless of whether italic or bold printer fonts exist (common examples are symbol fonts such as Zapf Dingbats or Symbol, for which there are no italic or bold printer fonts). With no associated printer font, a styled screen font will output unstyled, as the default font or not at all. Do not trust your screen - always check that Printer fonts are available before styling bold and/or italic

Outline and shadow text created by style menus should be avoided. Most desktop printers will not successfully show the final printed result, and you may get unexpected or undesirable results.

Fine lettering

Thin lines, rules, medium and small type sizes should be reproduced at 100% (solid) of only a single colour wherever possible.

Do not use rules defined as "Hairline" in your DTP application. Desktop printers and similar devices will not give an accurate representation of a hairline rule on your proofs.

Keep to a minimum rule weight of 0.25pt for a solid single colour.

Reversed out lettering

Reversed 1-1 out lettering, or knocked-out type, should be out of a minimum of colours. Type or objects smaller than 10pt in size should ideally be reversed out of one colour only. Small letters reversed out of multiple colours - particularly fonts with fine serifs - will show colour in white type areas even with the slightest mis-registration on press. Check to ensure that reversed-out lettering does not become illegible due to the text's background.

Tints and backgrounds

If you wish to reproduce a large solid black background I would recommend that the black prints at 100 per cent, along with a 40 per cent cyan tint to provide more density. This is often referred to as a "shiner", and produces what is sometimes called a "rich black".

The inclusion of a common colour background or strap heading across several pages of a feature or sections of a magazine can draw attention to the natural minor variations in colour balance that occur across a press/presses and during a press run. This can be minimised by creating these common colours out of as few process colours as possible. Give careful consideration to the use of one, or perhaps two colours to produce the common colour. Such a colour will enable a more consistent reproduction than the same object defined using all four process colours. However, certain two-colour combinations can also be prone to unattractive colour shifts - particularly when both colour values are midtones. Two-colour combinations where one colour is considerably higher than the other prove more stable, producing a more consistent, balanced result.

To assure accurate reproduction on press it is advisable to supply a colour swatch or contract-colour proof.

Tracking

Tracking occurs when ink is consumed by an area of a sheet with a high percentage of one or more colours, creating a deficiency of that colour within a later area running in track. This effect is more evident on heavy tint areas running across the sheet. To avoid the effects of tracking it is important to consider the final imposition and design your layout accordingly.

Black overprint

100% black elements will automatically overprint other colours. This prevents normal black text knocking "holes" in tints. Therefore, it is important that larger 100% black page elements, such as boxes or very large point size text, do not have variations in colour beneath them. These will show through in the printed page. Alternatively a "shiner" (see above) can be used to produce a heavier, more consistent solid. If a black element is overprinting a four-colour image, include at least 1% pf CMY in your black to ensure the picture does not show through the black.

Trims and Bleeds

All page content that runs to the edge of the page must extend off the page by a minimum distance of 3 mm. This minimum distance is referred to as bleed. If bleed is not applied there is a risk of an unsightly white area appearing at the bleed edge.

Elements that do not bleed should be a minimum distance of 5 mm from the edge of the page. This is referred to as the margin. Elements closer to the edge than this standard risk being trimmed off during the finishing process.

Do not attempt to place text sitting exactly on the trim - you will almost certainly be disappointed with the finished trimmed result.

Consideration should be given to the binding style when setting the margins.

For perfect-bound titles consideration should be given for the area in the backs lost in the spine glueing.

For wire-stitched titles remember that larger paginations cause "bulking" resulting in the centre pages of the magazine being considerably shorter in width than the pages at the front and back. The uneven fore-edge is trimmed away after it is stitched. You may wish to allow a larger fore-edge margin in such cases or a larger margin in the backs to allow for "feathering" at the imposition stage. Pages that read across the spine cannot be feathered so attention must be paid to the fore-edge to avoid important content being trimmed away. Check with your Production Controller at Headley Brothers for advice on how to proceed.

Particular attention must be paid to the covers of perfect-bound magazines. The cover is glued along the spine and attached to the first and last page of the contents and can lose an area of around 6-8 mm in the "hinge". Check the Downloads Page for the PDF "DPS For Covers Template" that will guide you in dealing with this.

Perfect Binding

Perfect Binding

Paginations below 56 pages are not suitable for perfect binding. Depending on the weight and bulk of the paper, fewer pages than this do not produce a spine of a viable width for the perfect binding process. Please consult your Production Controller for advice.

Elements across spreads

Accurate alignment of elements that go across a spread cannot be guaranteed. Items that can look bad across spreads on a final printed result are: rules; tint edges (especially diagonals); text and lineart. If it is necessary to run a line of text across a spread make sure the spine falls between words.

This is even more evident in perfect-bound titles which cannot be opened out flat. There is always a certain amount of the page in the backs that cannot be seen. To overcome this, pages which cross a spread should be "thrown out". Check with your Production Controller at Headley Brothers for advice on how this is achieved.

Ink Rubbing

Ink can be transferred through abrasive contact on press and bindery handling systems during the manufacturing process. Matt and silk/satin papers are particularly susceptible to ink rubbing. Consideration can be given to this at the design stage. Where possible avoid facing pages of heavy ink coverage against white, unprinted pages.

Where possible avoid designs where the outside front cover is heavily inked and the outside back cover has large areas of white space or vice versa.

If this is unavoidable, consider a seal, which can sometimes prevent marking.

Web growth

Paper has a tendency to expand as it absorbs moisture and shrink when it loses moisture. In the heatset web offset process heat is applied to the paper in order to flash off solvent and dry the ink. After heating the paper is cooled, and a layer of silicone emulsion is applied to "recondition" it. The heating of the paper removes a percentage of the moisture content which cannot be replaced in the printing process. The width of the web will have reduced by several millimetres when it leaves the press, which results in about one millimetre of shrinkage per page.

In sheetfed printing the opposite occurs. Paper takes up water in the printing process and may stretch due to water absorption.

When sheetfed covers are bound with web offset sections, the covers are trimmed flush with the inner sections. After the trimming the covers release moisture into the air and the web offset sections absorb moisture from the air. The covers may shrink slightly and the web sections will grow and hence show a difference in size. Since the industry-accepted best-practice is to run paper grain parallel to the spine, web growth beyond the sheetfed cover will normally be evident on the fore-edge.

This effect is common within the printing industry and is most often seen when sheetfed covers are bound with web offset sections.

It may be possible to minimise the impact of this effect by careful design of the cover and page one of the content. Speak to your Production Controller at Headley Brothers for advice.

designdisease.com

How Printing Works

To start off, a basic knowledge of how different types of printing work, while not necessary, will help you understand what it is you are doing when clicking that ‘print’ button.

There are many types of printers: laser jet, bubble jet, thermal printers, inkjet, etc. Inkjet printing is probably what you will come across and use the most. Inkjet printers use liquid ink to form the images you print. Usually inkjet printer will contain either ink cartridges or ink tanks, the difference between the two being that ink cartridges have inbuilt print heads while ink tanks are simply a container.

The ink is “sprayed” or dropped onto the page drop by prop by the printheads, building up the image you are printing

CMYK and DPI

One of the most important things to understand is how colours work when printing. Your basic inkjet printer usually will use 4 cartridges: one black, one cyan, one magenta and one yellow, CMYK. Using the CMYK colour model, the printer can lay down a combination of cyan, magenta, yellow or black creating pretty much any colour you would need. White is not needed and in a way is simulated by a lack of dots of colour, showing the white paper behind it, creating either white or a light colour.

When designing for print it can be best to make sure you either design or convert to CMYK before printing as colours will appear differently than when using RGB, but we’ll talk more about that later.

Another important factor is resolution and DPI. What resolution you design and print at really depends on how high quality you want the image to be and what sort of limitations your printer has. Due to printers having the limitation of only using 4 colour cartridges, the DPI has to be considerably higher than when displayed on a monitor to be able to replicate the more complex colours. When designing for print, for example the minimum DPI (dots per inch) for a magazine or leaflet will usually be 300, all though the higher the resolution the better the image will look.

Designing For Print

Designing specifically for print is not the same as designing for digital and web use, in fact it can be a little complicated.

As mentioned before, traditionally, when designing for print you should use CMYK, and this is still the case when using top end printers. The complicated part is that a lot of modern day inkjet printers don’t actually accept CMYK data, even if you send a file to print from photoshop with a CMYK colour mode, the printer will convert any data sent over into and RGB colour mode. So it’s hard for me to tell you what mode you should be designing in as it will be different with each printer you use.

Personally when starting a new document for print, I would recommend going with RGB anyway in the first stages of design. The reasons behind this being: RGB file sizes are smaller, some filters and effects don’t work when in CMYK and RGB has a larger colour range. Then once you are ready to print, convert to CMYK if your printer specifies that it can receive CMYK data, the only down side to this being a slight colour loss/change which you will be able to correct.

Now when it comes to DPI settings it is pretty simple. 300 DPI will almost always be as high as you need to go when designing for print. At this resolution, the human eye cannot distinguish between the dots from a regular reading distance, having a higher resolution would usually be pointless.

If printing something that will not be viewed up close, such as a poster or banner, the resolution can be lower, usually around 150 – 200 DPI is good. When designing for something much larger that will be viewed from further away, for example a large billboard, it is common for the resolution to be as low as 12 – 15 DPI.

With some of the larger prints you are probably not printing it yourself, so it’s always good to ask what sort of resolution and colour mode the printer requires.

Paper Stock

www.bbc.co.uk

Paper thickness is measured in grams per square metre (gsm). This is the weight of one square metre of the paper.

Most paper is manufactured from recycledboards and paper. Virgin paper is made from 100% wood pulp and contains no recycled material.

Different types of paper and board have different uses, as shown in the table below:

Types of paper and their uses

Type, Description and uses

Layout paper

- lightweight, thin white paper

- used for initial ideas

- takes colour media well

- low cost

Tracing paper

- thin, translucent paper

- making copies of drawings

- high cost

Cartridge paper

- good quality white paper

- available in different weights

- general purpose work

- can be used to make simple models

- medium cost

Bleedproof paper

- smooth, hard paper

- used with water-based and spirit-based felt-tip pens

- medium cost

Coloured paper

- many different types

- available in different thicknesses

- used for mounting finished work

- used to apply coloured surfaces to models

- low to medium cost

Grid paper

- printed square and isometric grids in different sizes

- a guide for quick sketches and model-making

- low cost

Print Processes

www.howstuffworks.com

There are nine main types of printing processes:

- offset lithography - what we are exploring in this article

- engraving - think fine stationery

- thermography - raised printing, used in stationery

- reprographics - copying and duplicating

- digital printing - limited now, but the technology is exploding

- letterpress - the original Guttenberg process (hardly done anymore)

- screen - used for T-shirts and billboards

- flexography - usually used on packaging, such as can labels

- gravure - used for huge runs of magazines and direct-mail catalogs

www.treetopdesignandprint.com

Print processes explained

Lithographic Printing

The main printing process used throughout the world and encompasses a number of different terms including:

Offset Printing, Litho, Sheet Fed, Web Offset, Continuous.

It is a

planographic process where the image and non-image are on the same flat printing plate. The image areas are processed to accept ink and repel water. The non-inage areas are processed to accept water and reject the greasy ink. So by wetting the plate and then inking it, the image area is able to transfer the ink to a blanket cylinder and then from there to the paper (the offset principle). The printing plate never comes into contact with the paper.

Litho plates are made by a variety of methods but most modern print factories use computer-to-plate (CTP) systems which are created direct from the computer files rather than having to output film first.

Digital Printing

Is primarily used for short runs of less than 1000 or for items that need to be individually personalised with text and/or images. Digital printing requires less set-up than other methods but does not gain from economies of scale.

Digital printing uses a dry ink process where the ink does not permeate the paper unlike wet ink. The dry ink is held in place by applying a layer of fuser oil and a heat process.

Large Format Printing

This process uses inkjet printing machines that can print widths up to 3.5m and virtually any length. Large format printing is usually used to produce short run posters, banners and point of sale material and the end results can be lightfast and permanent.

Silk Screen Printing

This process uses a stencil which is mounted on to a fine screen material. The ink is passed through the stencil and screen onto the substrate.

Screen printing can be used on virtually any substrate and any shape using any kind of ink.

Flexography

This process uses a rubber plate and very thin inks and is similar to the original letterpress printing techniques. This is a specialist process and is used most commonly on plastic carrier bags.

Gravure Printing

This process uses an engraved image which is flooded with ink and the surplus is scraped off with a blade, the plate is then pressed onto the paper. This process can produce very intense colour on very low grade paper and so is a popular process for long runs like Sunday newspaper supplements.

.jpg)